Restriction of Hazardous Substances Directive (RoHS)

Restriction of Hazardous Substances (RoHS) is a regulation of the European Union (EU), which originated in 2002 and was officially adopted in 2006. RoHS regulates the use of ten substances in electrical and electronic products that may be harmful to both humans and the environment.

One of the major objectives of the RoHS directive is to address the concerns related to the increasing volume of waste electrical and electronic equipment (WEEE) arising in the EU region. Restricting the hazardous substance at the point of manufacture is the most effective way to address this issue. Initially, the RoHS directive restricted four heavy metals and two flame retardants as per Annex II and was later amended by adding four phthalates.

Manufacturers, retailers, and suppliers of electrical and electronic products are required to abide by various regulations about RoHS specific to their target market.

Restricted Substances List & Acceptable Limits under RoHS

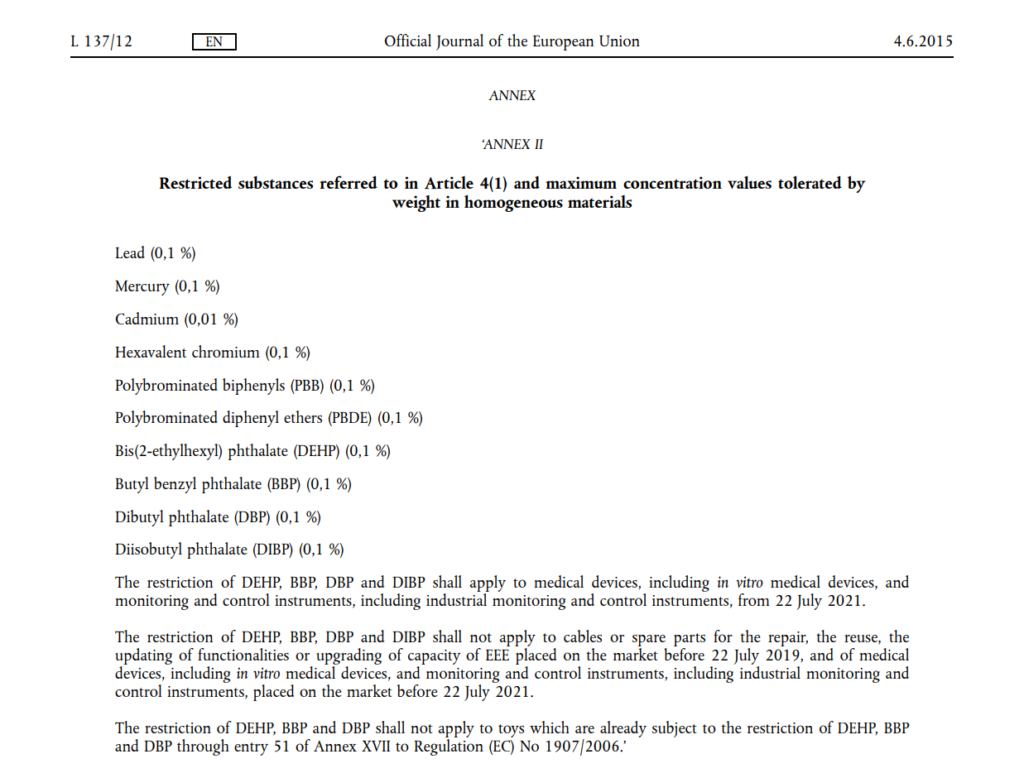

The substances that are currently

included in RoHS and their maximum allowable limits are listed in the table

below:

S.No. | Substances | Maximum limit (ppm) |

1 | Cadmium | < 100 |

2 | Lead | < 1000 |

3 | Mercury | < 1000 |

4 | Hexavalent Chromium | < 1000 |

5 | Polybrominated Biphenyls | < 1000 |

6 | Polybrominated Diphenyl Ethers | < 1000 |

7 | Bis (2-Ethylhexyl) phthalate | < 1000 |

8 | Benzyl butyl phthalate | < 1000 |

9 | Dibutyl phthalate | < 1000 |

10 | Diisobutyl phthalate | < 1000 |

Difference between RoHS 1, RoHS 2 & RoHS 3

RoHS 1

RoHS 1, also known as Directive 2002/95/EC, was published in 2002. Its scope was to restrict the use of the first six hazardous substances mentioned in the above table. Additionally, it mandated that all applicable products sold in the EU after July 1, 2006, should comply with RoHS.

RoHS 2

Directive 2002/95/EC (RoHS 1) was revoked and replaced by Directive 2011/65/EU (also known as RoHS 2 or RoHS Recast). The RoHS 2 became European Law on 21 July 2011 and took effect in EU Member States on 2 January 2013. The RoHS 2 broadened the scope of products covered in RoHS 1 and imposed new obligations on Electrical and Electronic Equipment (EEE) manufacturers and importers.

The RoHS 2 directive included medical devices and monitoring and control instruments to its categories of products and established different compliance deadlines for each category. There are a few exemptions to this rule, such as aerospace and military equipment, large-scale fixed installations (LSFI), non-road mobile machinery, active implantable medical devices, etc.

Click here to read more about RoHS-exempted product categories.

The RoHS2 Directive restricts the use of lead and other potentially hazardous substances including Cadmium, Mercury, Hexavalent Chromium (Chromium VI), Polybrominated Biphenyls (PBBs) and Polybrominated Diphenyl Ethers (PBDEs) contained in electrical and electronic products. With the exception of cadmium, which has a limit of 0.1% or 100 ppm by weight of homogenous material, RoHS restricts these chemicals to 0.1 percent or 1,000 ppm.

According to the RoHS 2 directive, it is mandated that importers or manufacturers of products under a RoHS category should conduct conformity assessments and affix CE markings on all products that comply.

RoHS 3 (EU 2015/863)

RoHS was amended in 2015 (EU/2015/863) to include “Category 11” (catch-all) products and four additional substances (phthalates) to the original list of six. This directive took effect on July 22, 2019. Non-compliance with RoHS 3 can lead to huge fines and legal consequences.

The four phthalates included in RoHS 3 list are Bis(2-ethylhexyl) phthalate (DEHP), Butyl benzyl phthalate (BBP), Dibutyl phthalate (DBP), Diisobutyl phthalate (DIBP).

An extension period of two years was given to medical devices to meet RoHS 3 compliance.

“The restriction of DEHP, BBP, DBP and DIBP shall apply to medical devices, including in vitro medical devices, and monitoring and control instruments, including industrial monitoring and control instruments, from 22 July 2021.”

Click here to read more about the latest list of RoHS-impacted product categories.

Many global Restriction of Hazardous Substances (RoHS) requirements are already in place or going through their appropriate government process. See more here.

Does RoHS applicable to your business?

RoHS will be applicable to any entity that sells electrical or electronic products, equipment, components, sub-assemblies, cables, or spare parts directly to RoHS-directed countries, or sells to resellers, distributors or integrators that in turn sell products to these countries.

How to be RoHS Compliant?

Businesses will have to confirm that none of the targeted hazardous substances exceed their threshold of 0.1% (or 0.01% for cadmium) at the homogeneous material level of every component and material in your product. The two different approaches available are mentioned below:

- Analytical testing

- Documentary approach

The documentary approach is highly recommended for complex products. It should be carried out in accordance with the IEC 63000 standard, as mandated by Europe RoHS.

Are RoHS and REACH the same?

No, they are not the same. While both the EU REACH Regulation and EU RoHS Directive have the same goal to reduce and restrict substances that can be considered harmful to humans and the environment, but there are many differences between the two legislations.

RoHS stands for the Restriction of Hazardous Substances and REACH stands for the Registration, Evaluation, Authorization, and Restriction of Chemicals. REACH is a regulation and RoHS is a directive in the EU.

The major difference is that REACH covers almost all products and has a broader scope, whereas RoHS only applies to the electrical and electronic equipment (EEE) industry. As of 30 November 2022 RoHS covers only 10 hazardous substances and focuses on those used in Electrical and Electronic Equipment (EEE), REACH will target and regulate the use of thousands of substances and is not limited to the EEE industry.

Whenever there is an overlap between the two legislations (REACH & RoHS), the strongest restriction (i.e. the lowest maximum concentration) should be applied.

|

RoHS |

REACH |

|

RoHS is evaluated at the homogenous material level |

REACH is evaluated at the article level |

|

RoHS restricts 10 hazardous substances in electrical and electronic equipment |

REACH applies to all chemicals |

|

Instructions but no enforcement on how to comply |

Has a defined process that must be followed for risk and chemical management |

|

RoHS is an EU Directive |

REACH is an EU regulation |

What is a homogeneous material in RoHS?

A homogeneous material is either:

- A material with a uniform composition throughout; or

- A material that consists of a combination of materials, that cannot be disjointed or separated into different materials by mechanical actions such as unscrewing, cutting, crushing, grinding or abrasive processes.

Examples of homogeneous materials include a plastic cover to a computer screen, a copper wire inside a cable, and the soldered part of a solder joint.

All EEE consist of many different homogeneous materials and the maximum concentration values are applied to each of the homogeneous materials individually. Any sample taken from EEE by a Member State enforcement authority should not contain restricted substances above the maximum concentrations unless there is an applicable exemption.

What are RoHS substances?

There are 10 RoHS-restricted substances with specific maximum concentrations. They are Cadmium (Cd): < 100 ppm (0.01%), Lead (Pb): <1000 ppm (0.1%), Mercury (Hg): < 1000 ppm (0.1%), Hexavalent Chromium (Cr VI) < 1000 ppm (0.1%), Polybrominated Biphenyls (PBB): < 1000 ppm (0.1%), Polybrominated Diphenyl Ethers (PBDE): < 1000 ppm (0.1%), Bis(2-Ethylhexyl) phthalate (DEHP): < 1000 ppm (0.1%), Benzyl butyl phthalate (BBP): < 1000 ppm (0.1%), Dibutyl phthalate (DBP): < 1000 ppm (0.1%), Diisobutyl phthalate

(DIBP): < 1000 ppm (0.1%)

Do you know the application of RoHS substances in products or product categories?

Is RoHS Mandatory in Europe (EU)

Yes, RoHS compliance is required for all applicable products (EEE) in the EU market since July 1, 2006.

Is RoHS a legal requirement?

The RoHS 1 directive was officially adopted on 1 July 2006 and become law in each member state. This directive restricts (with exceptions) the use of 10 hazardous substances in the electronic and electrical equipment industry.

How much lead is allowed in RoHS?

The Lead (Pb) content should be less than 1000 ppm or 0.1%.

What does RoHS mean?

Restriction of Hazardous Substances (RoHS) Directive.

When was RoHS implemented?

RoHS 1 (Directive 2002/95/EC) took effect on 1 July 2006 and become law in each member state.

Is RoHS applicable to non-electronic products?

Technically speaking, no, however, products or articles sold in the EU must follow the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation. All the 10 RoHS-restricted substances are also restricted under REACH regulation. Therefore, if a product isn’t RoHS-compliant, it’s unlikely to be REACH-compliant.

Do RoHS substance restrictions apply to the production process?

No, the restrictions are only applicable to finished EEE. The restricted substances may therefore be used in the production process, as long as they do not violate other regulations and the finished EEE does not contain the substance above the maximum concentration values.

Do components have to comply with RoHS?

As per RoHS 2, the electrical and electronic equipment (EEE) has to meet the requirements of the Directive. Since equipment consists of many different components, the EEE itself can only meet the substance requirements if all its components and parts meet the substance restriction requirements of RoHS, including non-electronic or non-electric components like fasteners or the plastic case of a desktop computer. Therefore components being used in finished EEE or for repair or upgrade of used EEE, which is in the scope of RoHS must meet the substance restrictions according to Art. 4 but do not need CE marking.

Does packaging have to comply with RoHS?

No. As there are separate regulations or standards available for packaging materials, usually packaging materials are out of the scope. RoHS is without prejudice to specific waste management legislation therefore packaging pursuant to the Packaging and Packaging Waste Directive is outside the scope of RoHS.

Are active RFID tags in scope of RoHS?

Yes. RFID tags (both active and passive) are in scope and should comply with RoHS as they meet the definition of EEE according to Article 3(1), unless they benefit from exclusion in Article 2(4).

What is RoHS analysis?

RoHS analysis is conducted in conformance with IEC 62321 to evaluate and determine whether a product contains RoHS-restricted substances at concentrations exceeding the legal regulatory threshold.

IEC 62321 is an International Standard, that specifies the determination of the levels of regulated substances like lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (Cr(VI)) and two types of brominated flame retardants, polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE) contained in electrotechnical products.

What are the different types of RoHS analysis?

There are two types of RoHS analysis, which involve screening analysis and precision analysis. Screening analysis does not use chemical techniques for the preparation and analysis of the sample, but precision analysis uses chemical techniques to analyze the samples. If the results are determined as a gray zone with the screening analysis, the inclusion is evaluated and determined with the precision analysis.

A) Screening analysis

Screening analysis is a simple analysis technique that is easy to perform. The analysis results are categorized as “Definite inclusion”, “Definite non-inclusion”, and “Gray zone” in which a determination cannot be made. If the analysis results fall in the gray zone, evaluation and determination are completed with the precision analysis technique.

B) Precision analysis

The precision analysis is more precise than the screening analysis. Precision analysis typically uses chemical techniques. A precision analysis is mostly used to determine the “Inclusion” or “Non-inclusion” of a sample that is determined as a “Gray zone” with the screening analysis.

How are products tested for RoHS compliance?

A combination of XRF (X-ray fluorescence), FTIR (Fourier-transform infrared spectroscopy), SEM (Scanning Electron Microscopy ), EDX (Energy Dispersive X-Ray Analysis) and AAS (Atomic Absorption Spectroscopy) used for screening of RoHS substances and to check out whether the product is RoHS compliant or not.

Is RoHS compliance required for the CE mark?

RoHS 2 is also a CE-marking directive. As per RoHS 2 directive (2011/65/EU), the CE mark should be affixed before electronic and electrical equipment (EEE) is placed on the EU market. The CE mark should be clearly visible, legible, and permanently affixed to the finished product or its nameplate. As the CE mark now covers RoHS compliance, the original green RoHS sticker with the checkmark is no longer required.

Does RoHS apply to batteries?

No, batteries are regulated under the EU Battery Directive (2006/66/EC and Amendment 2013/56/EU), regardless of their type or application. The Battery Directive restricts the use of cadmium to 0.002 percent (medical devices/equipment, alarm/emergency systems are excluded for cadmium), lead to 0.004 percent, and mercury to 0.0005 percent.